Wheel Balancer Computer Display

Electronic display wheel balancer with save-spacer wheel hood and wide weight tray cover for car, van and motorcycle wheels having maximum weight of 75 Kg and maximum rim diameter measurable with the automatic internal sensor of 28’’.

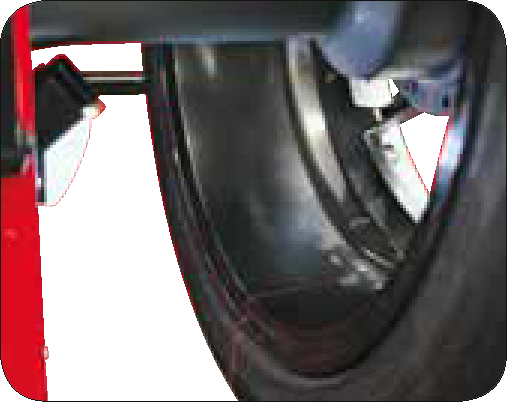

TECO 710 offers the following technical features: new internal digital gauge for automatic data entry system of distance and rim diameter with automatic selection of balancing programmes, automatic estimation program of wheel width parameter, automatic search of the balancing position, rim illuminator and Laser line system for adhesive weight positioning at 6 o’clock when ALU programs are selected.

The product is supplied complete with the following main software programs: static and dynamic balancing mode, 7 ALU programs dedicated to alloy rims including 2 ALU-P «Precision» programs, 3 motorcycle balancing programs, «Quick Optimisation» program and Run-Out visual control.